As the world becomes more connected, intelligent and automated, the role of sensors is expanding. Sensors can perform the critical task of collecting input from the environment and turning it into useful data in almost all industries, from healthcare and agriculture to manufacturing, communications, building systems and transportation.

However, every application needs sensors to provide the most valuable data. This means that engineers must constantly innovate to develop sensors that can more accurately detect conditions such as position, velocity, vibration and pressure, as well as temperature, humidity and fluid conditions. As manufacturers build sensors into more and more devices, the main trend is to get smaller, sturdier and more reliable.

The sensors developed by TE Connectivity work closely with our connectivity products, giving us unique insights into the innovation needs of different industries. We've seen countless ways sensors can improve our lives, but here are some of the most interesting developments.

Sensor-driven innovation in healthcare

One need only look at the health and fitness trackers that millions of people wear on their wrists to understand how miniaturized, high-performance sensors are driving advances in medical technology. But some of the most important innovations have occurred in professional applications.

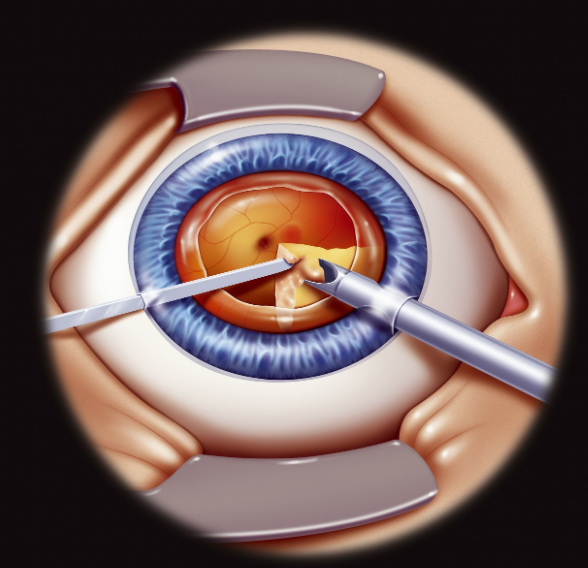

such as cataract surgery, which involves making a small incision in the cornea to remove the clouded lens. Applying just the right amount of pressure is essential to avoid damaging the eye, but it requires sensors to provide extremely precise pressure measurements in a tiny package. Today's advanced sensors achieve the balance of miniaturization and high performance required for minimally invasive surgical tools.

Sensors are crucial to providing the feedback surgeons need to work safely inside a patient's body. Force sensors let the surgical team know exactly when the cutting tool will be in contact with human tissue, temperature sensors can help protect nearby tissue from damage during laser surgery, and pressure sensors can control the most sensitive body parts in situations where gas is an important part of the surgery.

1.Improved sensor technology has also created new ways to perform traditional medical procedures and measurements

For example, blood pressure and heart rate monitoring is almost always done at every clinic or hospital visit, but a nurse is usually required to take these measurements. Today, high-performance piezoelectric film sensors are so sensitive that they can record a patient's pulse and breathing rate just by touch. By embedding these membranes into exam room tables and even waiting room chairs, patients' vital signs could be automatically monitored from the moment they enter the office, creating a better patient experience and allowing healthcare professionals to better collect data.

The move towards smart factories is expanding the role of sensors and the data they collect. For decades, industrial machines have relied on sensors to measure operating variables such as position and torque, as well as vibration, temperature and fluid characteristics critical to reliable performance. However, avoiding equipment failures requires regular maintenance, which can take important assets offline and slow down production.

From the factory owner's perspective, it is best to know exactly when the machines need maintenance to maximize uptime. With sensor systems, predictive maintenance is now possible to monitor machine performance, detect when excessive wear or failure is at risk, and alert operators to the need for attention.

2.Variables such as temperature and vibration usually indicate the underlying stress on the device

For example, taking output from temperature or acceleration sensors and comparing current levels to historical patterns can help a company detect when a machine is operating outside its safe range. The computing power required to perform this analysis can be achieved through sensors with embedded microprocessors that automatically alert when maintenance is required. However, some manufacturers may go a step further and combine sensors with wired or wireless connections to send performance data to the cloud, where machine learning or artificial intelligence can look beyond maintenance requirements for other opportunities to optimize device performance.

Perhaps the biggest promise (and challenge) of sensor technology is the development of fully autonomous, driverless cars. Sensors have become ubiquitous in modern vehicles, even if some are not obvious to the driver. TE provides a range of sensors to monitor electric vehicle (EV) motor and battery performance, oil characteristics sensors for internal combustion engines, humidity sensors for air conditioning units, and virtually every other type of system.

Still, most manufacturers and consumers want to see innovations that enable autonomous driving capabilities. The Society of Automotive Engineers defines six levels of vehicle automation, ranging from basic lane-keeping assistance and adaptive cruise control (Level 1) to parking assistance and collision avoidance (Level 2). These systems are in regular use today, often relying on optical sensors to detect potential crashes at low speeds or to keep the car in its lane. But the technical requirements for fully autonomous vehicles (level 5) are much higher.

To truly operate without driver control, the vehicle needs 360-degree visibility to detect what's going on around it, interpret what those signals mean, and calculate the appropriate actions based on conditions such as speed, weather conditions and surrounding obstacles. These calculations need to be done in milliseconds.

The basic sensor technology for these systems already exists. The real challenge is computing power: how do we design vehicles smart enough to act on the data they receive from the environment? Human behavior is another hurdle for driverless cars, as it will take a long time for many drivers to get used to fully autonomous driving or feel comfortable enough to fall asleep behind the wheel.

For these reasons, we believe fully autonomous driverless cars are still a long way off. At the same time, TE is committed to working with automotive customers to meet their sensing needs, such as adapting optical sensors to improve night vision, adding value to sensor components with processing capabilities, and combining our sensor products with wired or wireless high-speed data connections. By thinking of sensors as part of the technology platform and constantly looking for ways to add value to these systems, we are working to ensure that when the computing power and humans are ready for a world of fully autonomous, driverless cars, the sensing and connectivity technologies will be ready as well.